- Overview

- Recommended Products

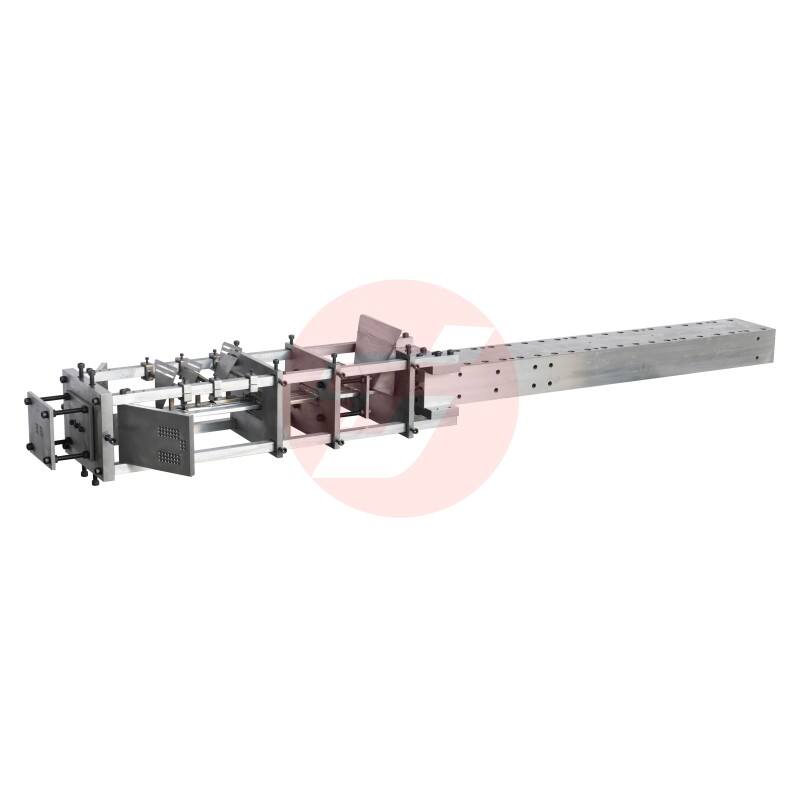

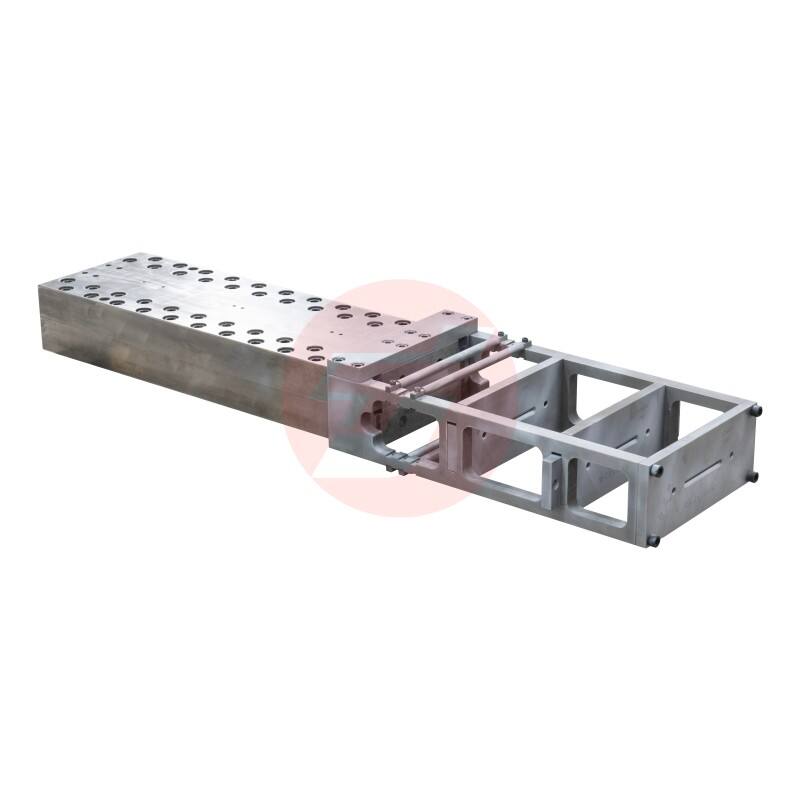

Product Description

The new energy composite material battery pressure strip is a type of new structural component, it is made by high-performance continuous fibers (such as carbon fibers and glass fibers) reinforced thermoplastic or thermosetting resin matrix, through advanced processes such as pultrusion or compression molding. They are specifically designed for the module fixation and restraint system of new energy vehicles battery pack (PACK) , replacing the traditional metal pressure strips. It is a crucial lightweight and high-safety solution within the battery pack.

Core advantages and features

Compared with traditional metal (such as aluminum alloy, steel) battery pressure strips, our composite material battery pressure strips have revolutionary advantages:

Ultra-lightweight design

Weight reduction up to 40%-60%: The density of composite materials is much lower than that of metals, significantly reducing the overall weight of the battery pack and directly enhancing the range of electric vehicles.

High strength and high modulus

Excellent mechanical properties: Through the directional reinforcement of continuous fibers, the product has extremely high specific strength and specific modulus. It has outstanding tensile and flexural properties, and can effectively withstand the expansion force during battery charging and discharging, as well as the impact and vibration during vehicle driving.

Outstanding corrosion and chemical resistance

Unfazed by harsh environments: Completely corrosion-resistant, it has extremely strong tolerance to chemical substances such as the electrolyte and coolant inside the battery pack. Its performance remains stable over a long period of use, eliminating the risk of strength reduction and safety hazards caused by corrosion of the metal strips.

Reliable insulation performance

Safety guarantee: The composite material itself is an excellent electrical insulator, which can effectively isolate the battery cell module and prevent short circuits and leakage risks that may be caused by the conductive nature of the clamps. This significantly enhances the system safety of the battery pack (SER).

Low thermal conductivity and flame retardancy

Excellent thermal management: Low thermal conductivity allows for a thermal barrier, reducing heat transfer between battery cells and modules, and delaying the spread of thermal runaway.

High flame retardant grade: In extreme circumstances, it does not support combustion and does not produce molten droplets, effectively enhancing the fire safety of the battery pack.

Design flexibility and integration

Free shaping: It can achieve integrated design with complex structures based on the internal space of the battery pack (such as integrating wiring clips, sensor brackets, etc.), thereby reducing the number of components and assembly steps.

Dimensional stability: The thermal expansion coefficient is more compatible with the battery cell, reducing internal stress caused by temperature changes.

Applications

This product is widely used in the power battery packs of various new energy vehicles, including:

Passenger vehicles: Battery modules fixation for pure electric vehicles (BEV) and plug-in hybrid vehicles (PHEV) .

Commercial vehicles: Large battery systems for electric buses and electric trucks.

Energy storage system: Constraints on battery clusters of fixed/ containerized energy storage stations.

Two-wheel vehicles: High-performance battery packs for electric motorcycles and electric bicycles.