Photovoltaic (PV) Frame Pultrusion Mold

Alternative names: Polyurethane pultrusion mold, composite material frame pultrusion mold, photovoltaic frame pultrusion mold, solar frame pultrusion mold

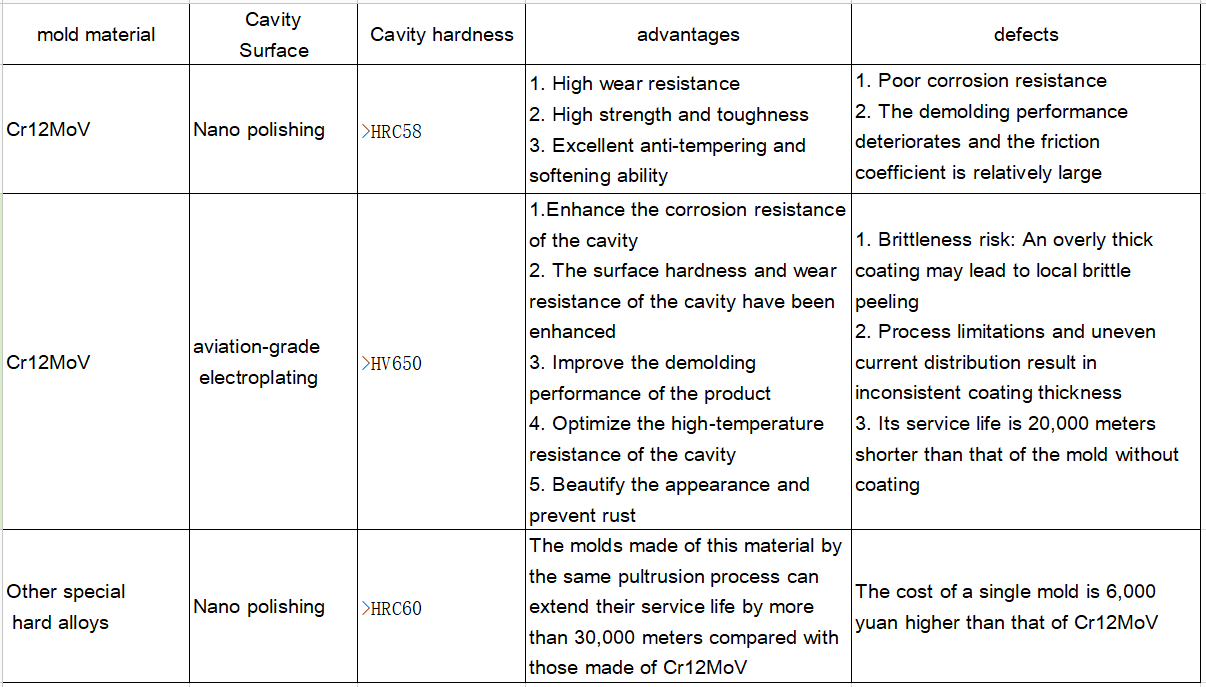

The following customization options can be made according to different needs

- Overview

- Recommended Products

Product description:

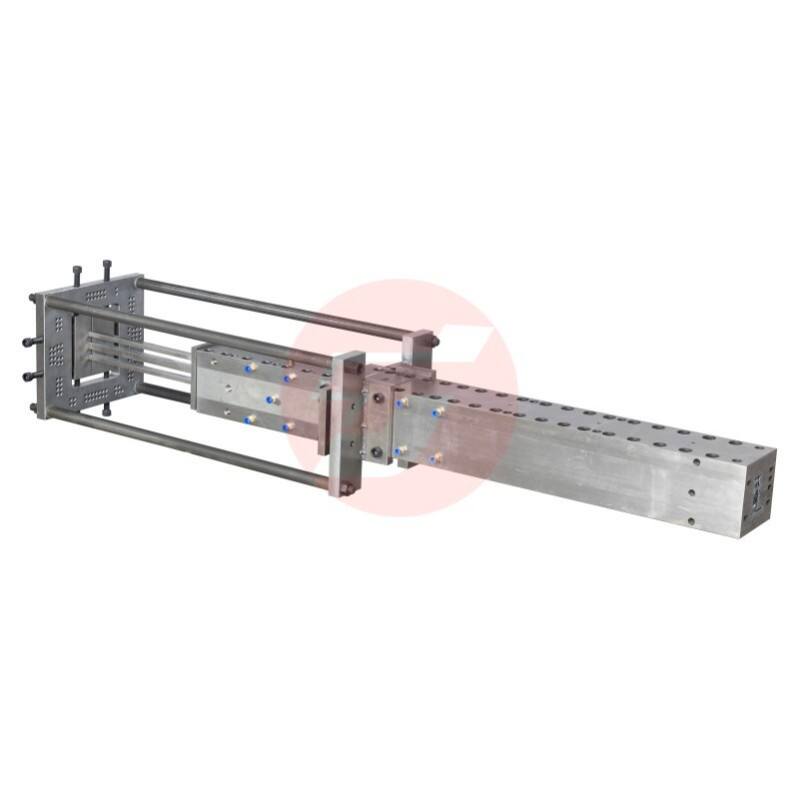

This mold is a photovoltaic frame mold, which adopts the production process of high-pressure glue injection for the upper and lower two pieces of mat. The mold tolerance is controlled within ±0.1mm to ensure that the frame can be perfectly matched with the photovoltaic module glass, backsheet and installation system.

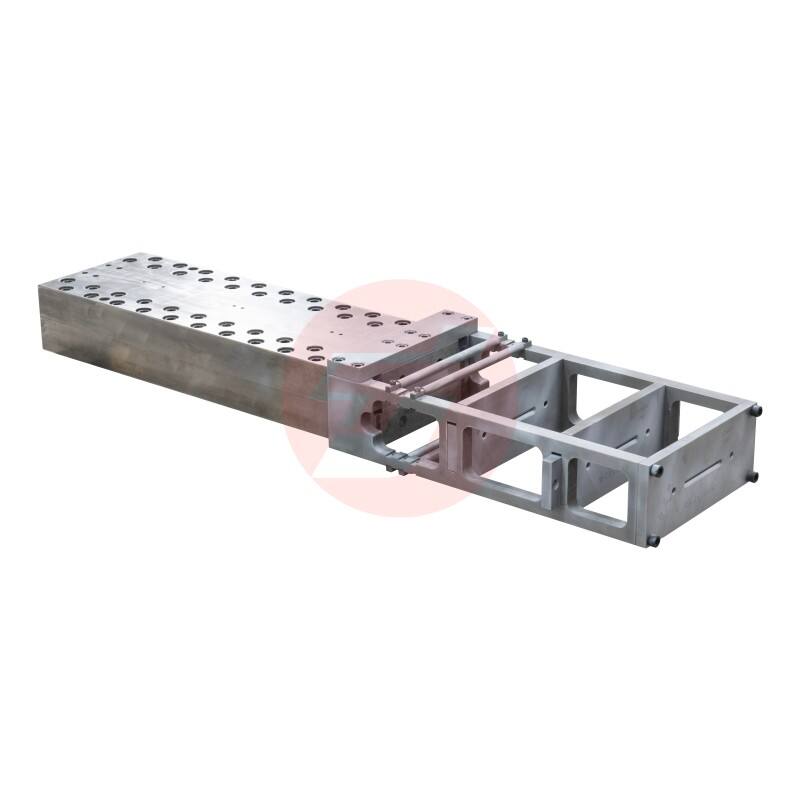

Mold Structure

1.Preformed Section:

Further compact and neatly arrange the fiber bundles, and more precisely shape the initial form to prepare for entering the heating curing section.

2.Heating and curing section:

The cavity is precisely equal to the size of the final product.

The exterior of the mold is heated by a heating plate system, providing the precise temperature required for resin curing (typically within the range of 120°C - 200°C depending on the resin system).

The fiber bundles impregnated with resin are heated in this section, and the resin undergoes a cross-linking and curing reaction, forming a hard composite material structure.

3.cooling section:

The cavity size has been slightly adjusted compared to the curing section.

Cooling water is passed through to cool and set the cured profiles, ensuring their dimensions are stable and they have sufficient strength to be pulled out of the mold without deformation.

Our company developed a preforming and immersion tank cooling equipment independently, it can stably produce for 15 days under the premise of ensuring the qualification rate, and the pultrusion speed can reach more than 2mm per minute.

Typical Application

New energy, photovoltaic power generation

The following customization options can be made according to different needs