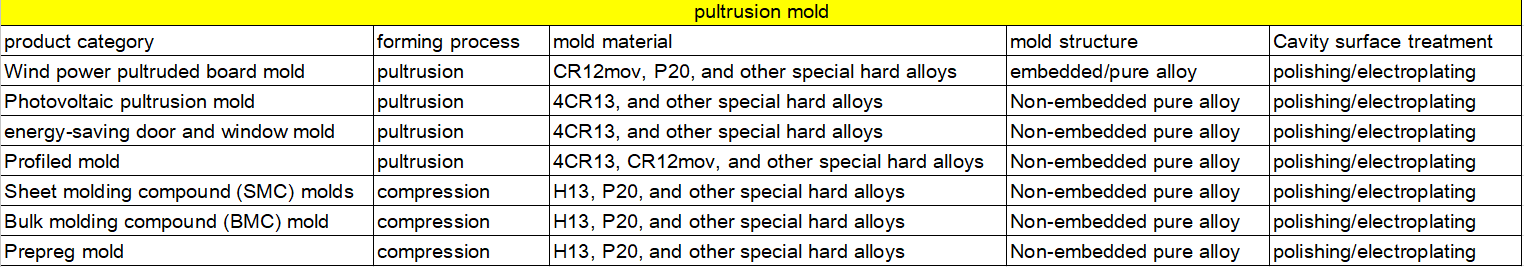

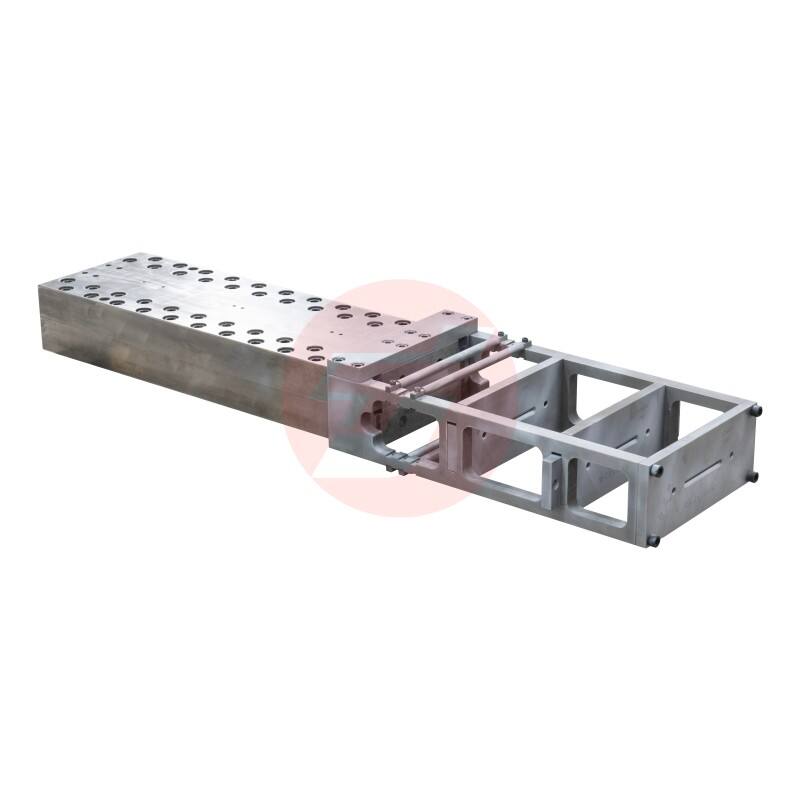

Wind turbine main beam plate pultrusion mold

Alternative names: Wind power pultrusion board mold, epoxy flat plate pultrusion mold, glass plate pultrusion mold

- Overview

- Recommended Products

Product description:

The mold adopts an inlaid design, and the inlaid structure brings two lows to the cost.

1.Low overall cost: The outer frame is made of ordinary steel, and the material and processing costs are much lower than those of a whole piece of high-performance tool steel.

2.Low replacement cost: When the working surface of the mold cavity (insert) is worn or damaged, only the insert needs to be replaced, and there is no need to scrap the outer frame.Extremely long service life; The inserts are made of super-hard hard alloy materials, with a hardness of over HRC58. The service life of a single mold can reach 150,000 meters, or even 230,000 meters. Wide range of application; It can meet the stable production requirements of pultruded plates with different cross-sectional thicknesses ranging from 1mm to 10mm.

Typical Application

Energy industry, pultruded plate reinforcing ribs for wind turbine blades

The following customization options can be made according to different needs