- Overview

- Recommended Products

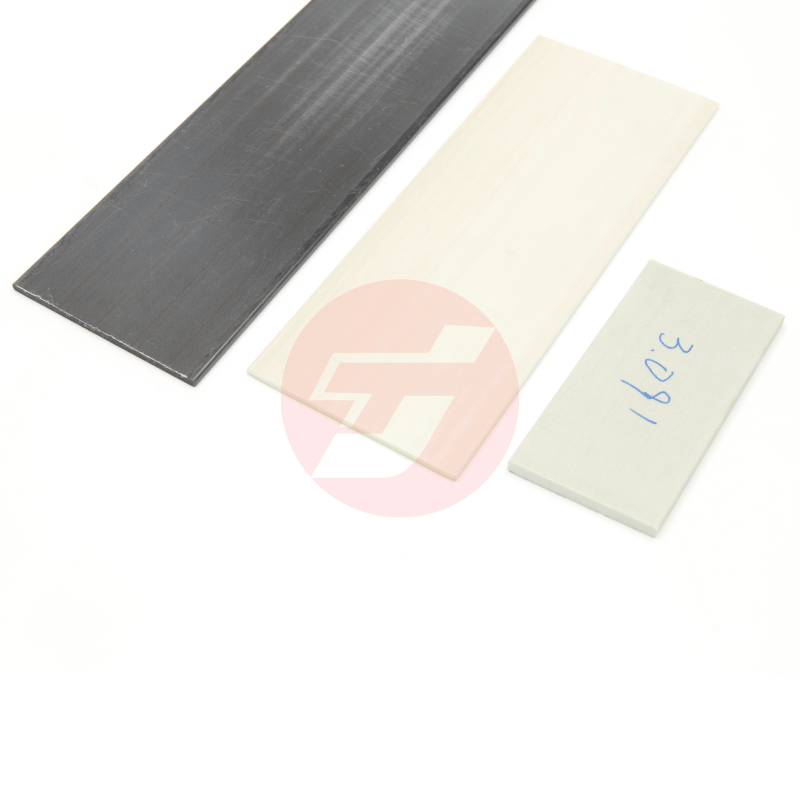

Product Description

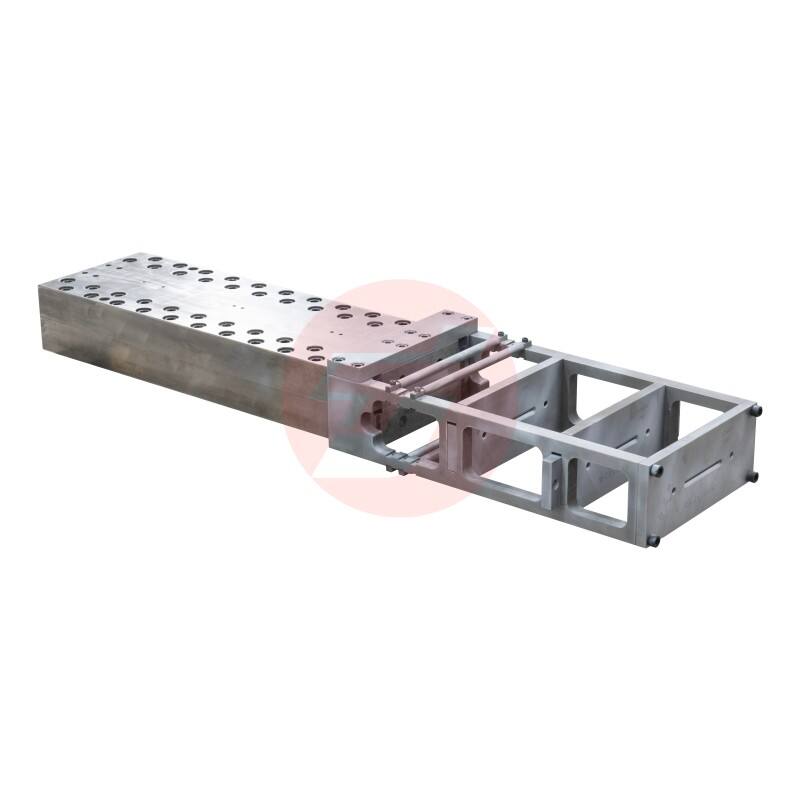

This product is an pultruded board produced by our company. The details are as follows:

High-strength and lightweight

Excellent mechanical properties

High fiber content (60%-80%): Continuous fibers (such as glass fibers, carbon fibers, etc.) are arranged directionally along the force-bearing direction, with tensile strength reaching 800-1500 MPa and bending modulus exceeding 40 GPa. This is superior to traditional molding or hand-laying process products. Excellent fatigue resistance: The performance remains stable under repeated loads, making it suitable for long-term load-bearing scenarios such as bridges and wind turbine blades.

The weight has been reduced by 50% to 70%.

The density is only 1.5 - 2.0 g/cm³, much lower than that of steel (7.8 g/cm³), thereby reducing the structural load. For example, in pultrusion.

Typical Application

Alternative to wood: Avoid depletion of forest resources in wetland walkways and garden landscapes.

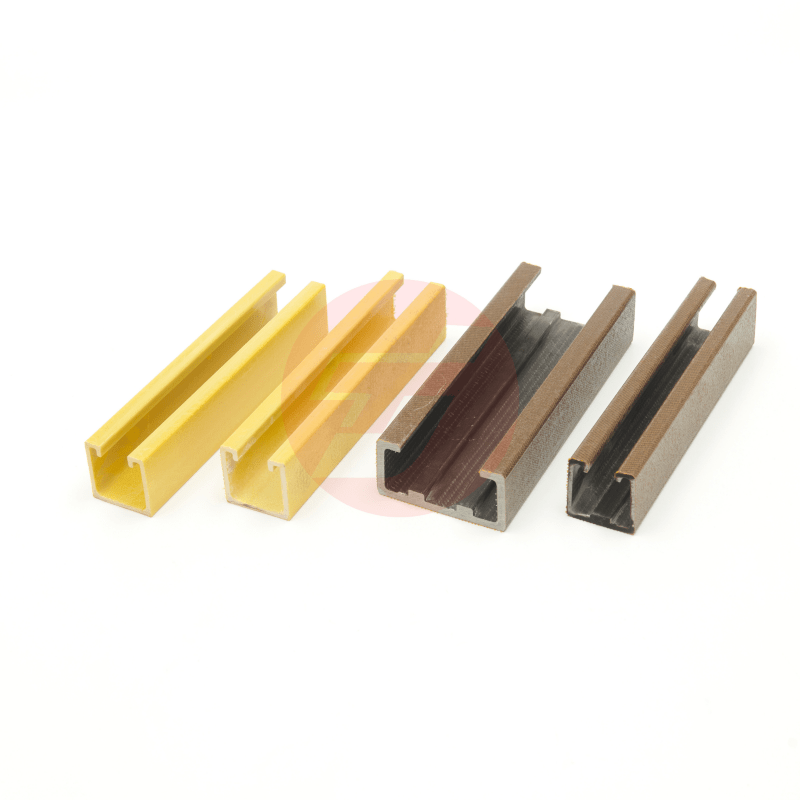

Architecture and Infrastructure Construction

Bridge reinforcement: The use of pultruded carbon fiber sheets for the reinforcement of the flexural strength of concrete beams has increased the construction efficiency by 50% compared to traditional steel cables.

Electrical equipment: Insulated pultruded grids are used on the platform of the substation to eliminate the risk of electric leakage.

The field of new energy

Wind turbine blades: High modulus pultruded sheets enhance the torsional stiffness of the blades, extending their lifespan by 20%.

Transportation

Rail Transit: The pultruded honeycomb panels are used in the interior of high-speed trains, being flame-retardant and reducing weight by 30%.

Logistics pallet: Corrosion-resistant, maintenance-free, and its lifespan is five times that of wooden pallets.