- Overview

- Recommended Products

Product Description

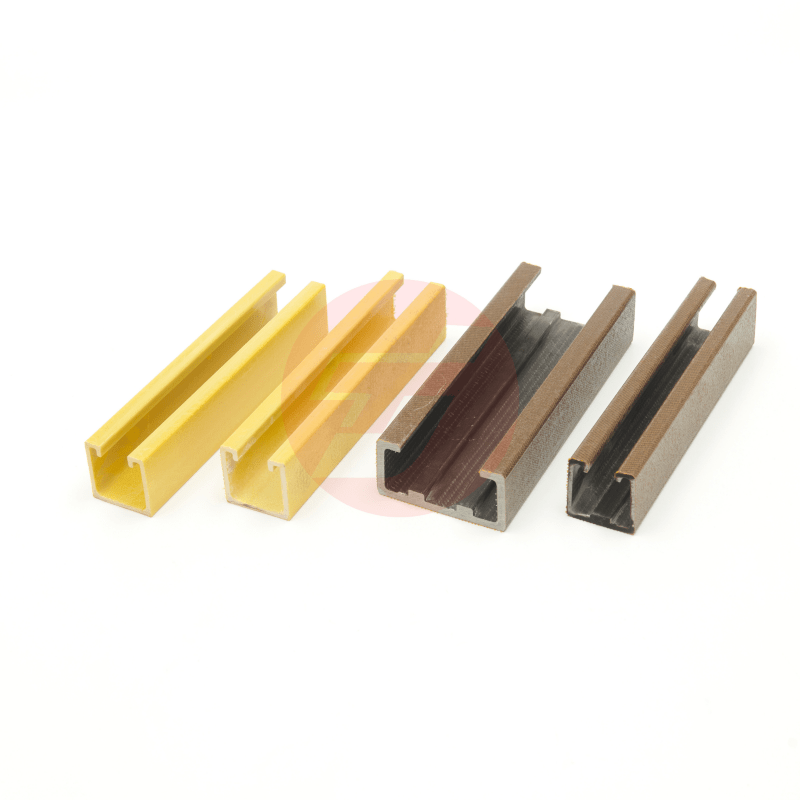

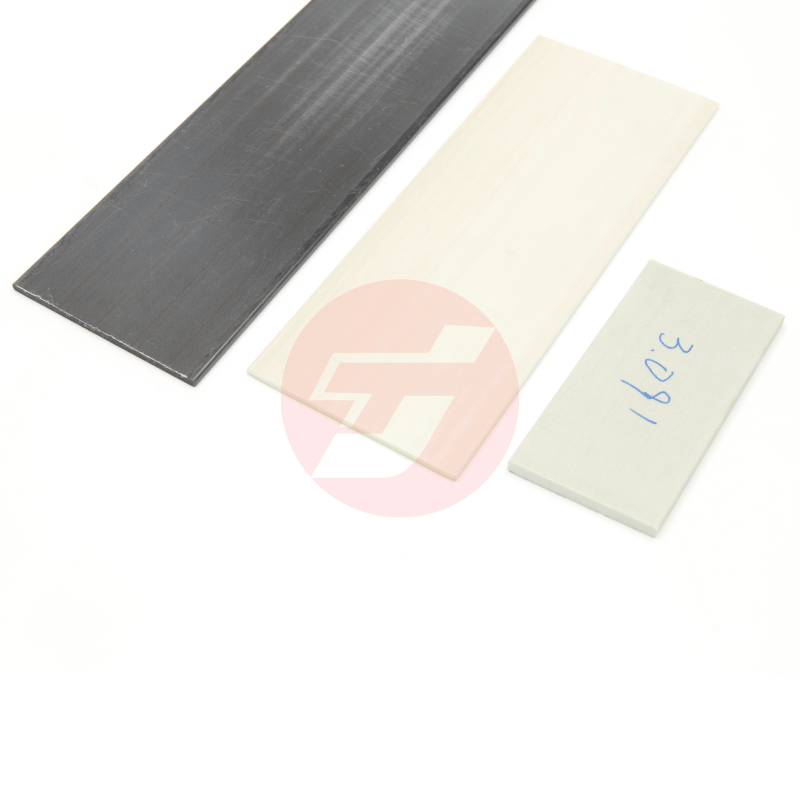

This composite material support is a photovoltaic support produced by our company through pultrusion. It comes in two types: fiberglass and basalt.

High-performance composite material products with fibers as reinforcement and resin as the matrix.

The advantages are as follows

Lightweight and high strength

The density of glass fiber composite materials is only 1.4 - 2.0 g/cm³, which is 1/4 - 1/6 of steel density. However, their mechanical strength can rival ordinary carbon steel, with tensile and bending strength reaching over 400 MPa. They are particularly suitable for weight sensitive scenarios (such as high-altitude cable supports).

Corrosion resistance and long service life

The fiberglass supports perform exceptionally well in harsh environments such as acids, alkalis, and salt fog, without any problem of electrochemical corrosion, and can have a lifespan of over 30 years. For instance, they are suitable for salt fog environments in offshore photovoltaic power stations or chemical pipeline supports, and are significantly superior to metal materials.

Insulation and Safety

The material itself is non-conductive and is suitable to use in power cable supports. It can prevent the risk of leakage and does not require additional insulation treatment.

Low maintenance cost

The surface is smooth and resistant to stains, do not need painting or frequent maintenance, this reduce the total life cycle cost.

Typical Application

Power cable support

It is suitable for scenarios such as cable trenches and tunnels, replacing traditional metal supports to solve the rusting problem, and enhancing safety and durability. The pre-installed design simplifies the installation process and is adaptable to complex laying environments.

Architecture and Infrastructure

It is used in engineering projects such as bridges, subways and high-speed railways to reinforce structures or as seismic components. For example, fiberglass reinforced plastic supports are used for concrete repair to enhance crack resistance.

Chemical Engineering and Marine Engineering

The corrosion-resistant property makes it an ideal choice for storage tanks and pipeline supports, especially suitable for areas with high salt spray in coastal regions or in corrosive medium environments of chemical plants.

The field of new energy

In photovoltaic systems, glass fiber composite material frames have gradually replaced aluminum alloys, and in the future, they may extend to the field of supports. The offshore photovoltaic industry has a great demand for salt-resistant supports, and glass fiber composite materials have significant advantages.