- Overview

- Recommended Products

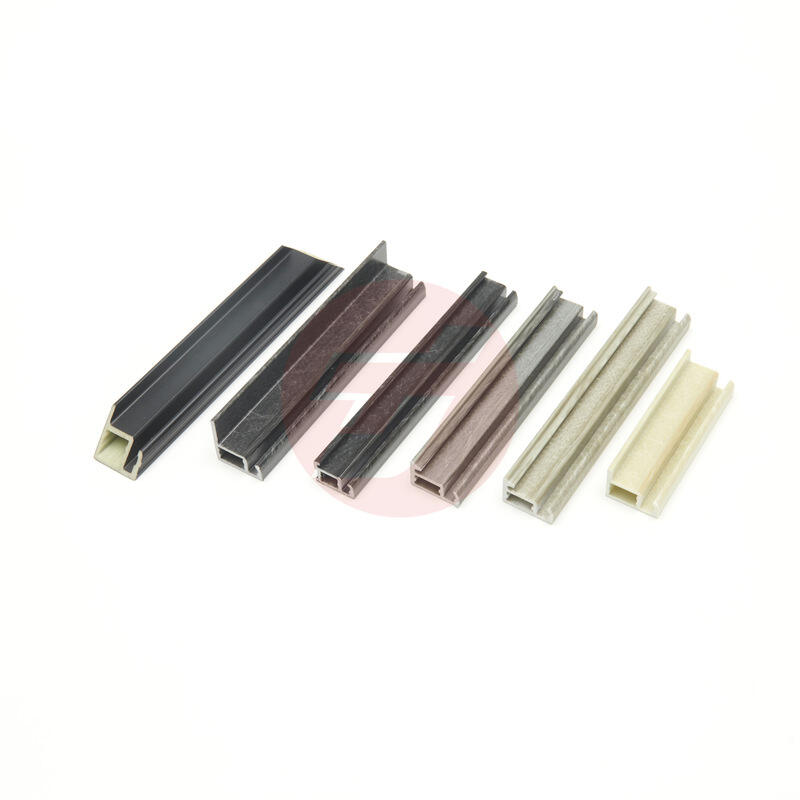

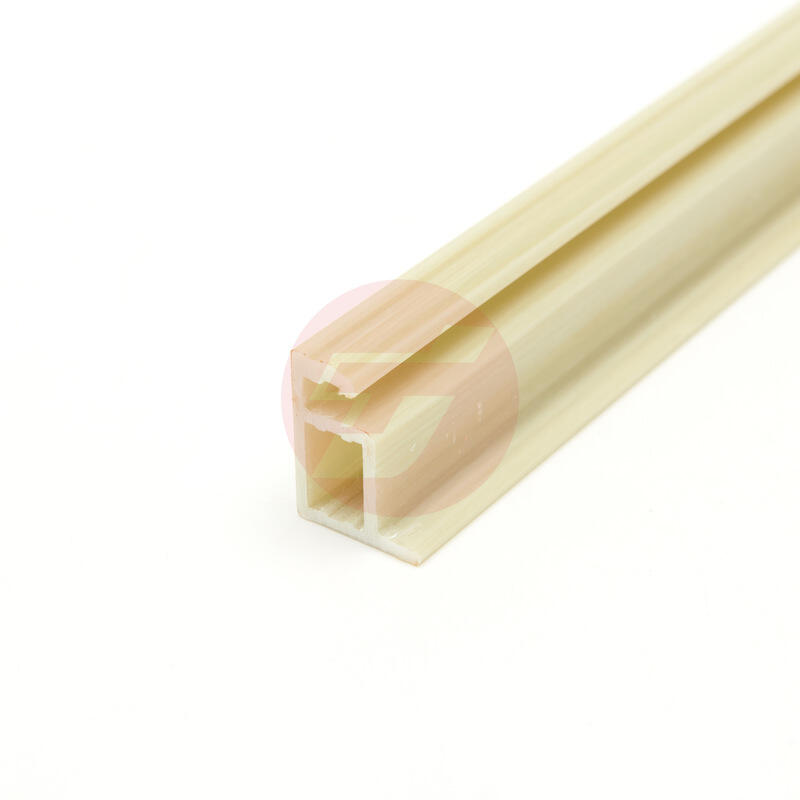

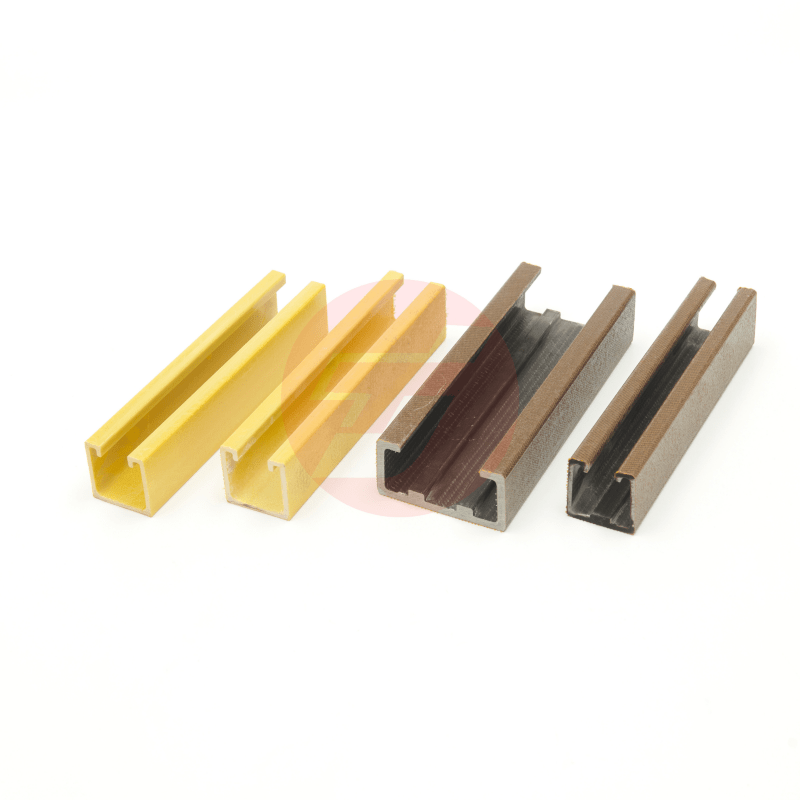

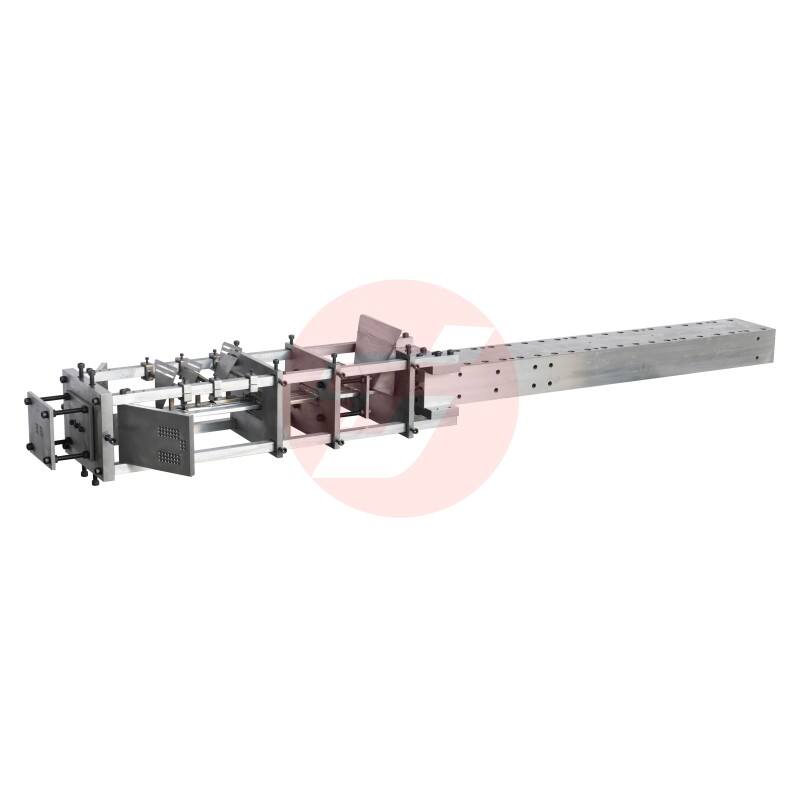

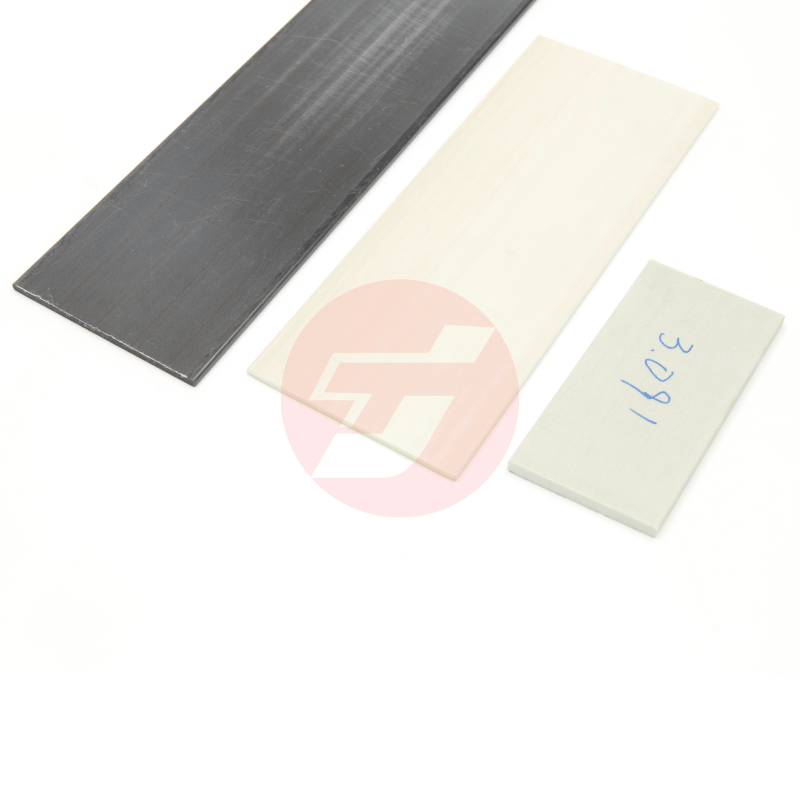

Product Description

The composite material frame, with its unique material properties and technological innovations, has demonstrated significant advantages in the fields of photovoltaics, construction, and transportation. Here is an introduction to its core advantages:

Lightweighting and high mechanical properties

Weight loss of 30-50%

The density of the composite material frame is only 1.5 - 2.0 g/cm³ (aluminum alloy is approximately 2.7 g/cm³), which can significantly reduce the overall weight of photovoltaic modules or building facades, and lower transportation and installation costs. For instance, when using a composite material frame for photovoltaic modules, each module can be reduced by 1.5 - 2.5 kg in weight, making it more suitable for rooftop distributed photovoltaic and scenarios with high load-bearing requirements.

High intensity and fatigue resistance

The tensile strength of glass fiber/carbon fiber reinforced composite materials can reach 500-1000 MPa, and the bending modulus exceeds 30 GPa, which is superior to that of aluminum alloys. Through the pultrusion or compression molding process, complex cross-sectional designs (such as multi-chamber structures) can be achieved, enhancing wind pressure resistance (up to 8000 Pa or more) and deformation resistance.

Weather resistance

It has a wide temperature adaptability and a low thermal expansion coefficient (< 2×10⁻⁶/℃). It can maintain its size stability even under an extreme temperature difference of -50℃ to 120℃, avoiding the problem of seal failure caused by thermal expansion and contraction. It is particularly suitable for harsh environments such as deserts and cold high altitudes.

Insulation and safety enhancement

Complete insulation property

The resistivity of the composite material frame is greater than 10¹² Ω·cm. This can completely eliminate the leakage risk of the photovoltaic module frame, do not need additional insulation treatment, this can ensure the safety of household photovoltaic power usage in humid environments.

Fireproof and flame-retardant performance

By adding flame-retardant agents such as aluminium hydroxide, the composite material frame can meet the UL94 V-0 level of flame retardancy standards, reducing fire hazards and meeting the requirements of building fire protection regulations.

Economic benefits and environmental advantages

Overall cost is lower

Although the initial material cost is slightly higher than that of aluminum (about 10%-15% higher), the reduction in transportation/installation costs, maintenance-free feature, and long service life of the composite material result in a 20%-30% reduction in the overall cost within 10 years. Taking a 1 GW photovoltaic power station as an example, using composite material frames can save over 5 million yuan in installation costs.

Typical Application

Offshore photovoltaics: With salt spray resistance properties, it is suitable for marine environments.

Lightweight roof: Reduces load, suitable for renovation of old factories. The German Next2Sun project achieved a weight reduction of 40%.